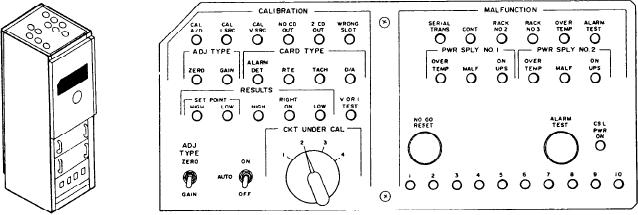

Figure 9-4.--S/CE No. 2 and S/CE No. 3 self-test panel.

calibration panel on or off or to set it for

indicators are labeled OVER TEMP, MALF, and

ON UPS. The first LED, labeled OVER TEMP,

automatic. In the OFF position the calibration

panel is disabled. The ON position allows the

illuminates red to indicate an overtemperature

operator to conduct adjustments and calibrations

condition in power supply No. 1. The second

of the various circuit cards. In the AUTO

LED, labeled MALF, illuminates to indicate a

position, the self-test panel allows for the

malfunction within power supply No. 1. The last

generation of the self-test signal that is distributed

LED, labeled ON UPS, illuminates red to indicate

to respective ECSS equipment. The four-position

the power supply is on UPS. The next three LED

rotary switch, labeled CKT UNDER CAL, allows

alarm indicators, under the heading PWR SPLY

the operator to select the circuit on the circuit card

NO. 2, are identical to the LEDs discussed for

to be tested.

power supply No. 1. The first push-button switch

located on the left side of the MALFUNCTION

MALFUNCTION Section

section is labeled NO GO RESET. The operator

Refer to section B in figure 9-3. The

uses this switch to clear the alarms on the CISE

MALFUNCTION section (B) consists of 13 LED

or respective S/CE. The other push-button switch,

status/alarm indicators, two push-button switches

located on the right side of the MALFUNCTION

and ten test jacks. This section provides the

section, is labeled SER CLK RESET (labeled

operator with a visual indication of a malfunc-

ALARM TEST on S/CEs No. 2 and No. 3). On

tion within the respective S/CE and the status of

S/CE No. 1, the operator uses this push button

that system. The first six LED alarm indicators

to reset the serial clock. On S/CEs No. 2 and No.

illuminate red to provide an indication of a

3, the operator uses this push button to conduct

malfunction in the S/CE (and the ECU for S/CE

tests of the S/CE alarms. The last LED indicator,

labeled CSL PWR ON, illuminates red to indicate

No. 1). The first LED, labeled SERIAL TRANS,

indicates a malfunction in serial transmission. The

that CISE console power is on. The 10 test jacks

second LED, labeled CONT, indicates a break in

along the bottom of the MALFUNCTION

continuity in the S/CE. The third LED, labeled

section allow the operator to read various data

RACK NO. 0 (RACK NO. 2 on S/CEs No. 2 and

test points within the S/CE.

No. 3), indicates a malfunction in the respective

BELL AND DATA LOGGERS

logic rack. The fourth LED, labeled RACK NO. 1

With all the equipment that must be monitored

(labeled RACK NO. 3 on S/CEs No. 2 and No. 3),

indicates a malfunction in the respective logic

and all the information that must be logged for

rack. The fifth LED, labeled OVER TEMP,

future reference, it would be nearly impossible for

indicates an overtemperature condition within the

a single operator to operate the console and write

in a log. For this reason, two line printers are

S/CE. The last LED in the first row, labeled ECU

designed to receive information from an ECU and

(labeled ALARM TEST on S/CEs No. 2 and

No. 3), indicates a malfunction in the ECU

log this information automatically. These line

(indicates an alarm test on S/CEs No. 2 and

printers, the bell logger and the data logger, are

identical in design and operation. The only

No. 3). The next three LED alarm indicators are

difference is in the information the printer is

under the heading PWR SPLY NO. 1. These

9-7