monitoring of up to 16 operator-selected param-

to receive data. The second switch, a two-position

eters and automatic printout if a parameter's

toggle switch labeled ON/OFF, turns the line

value changes by more than a preset threshold

printer on and off. The last switch is a two-

position, spring-loaded toggle switch labeled

(percentage).

TEST. This switch tests the printer operation by

DEMAND PRINT LOGGING.--The demand

printing out a test pattern when the operator raises

print logging function provides the operator with

the switch to the TEST position.

a printout of an individual item or a group of

items. To accomplish this, the operator dials up

the address for the information desired to be

FUEL SYSTEM

printed and depresses the print push button.

CONTROL EQUIPMENT

If either of the line printers should fail to

The fuel system control equipment is not

operate properly, the remaining operable printer

connected to any components of the ECSS. It is,

automatically assumes all logging duties. In this

however, an important electronic control console

event, the priorities for logging time, in order of

on the DD-963, DD-993, and CG-47 class ships;

highest to lowest, are as follows:

therefore, it is discussed in this chapter as is the

1. Bell logging

damage control console.

2. Alarm logging

The major components of this system include

3. Status change logging

the fuel system control console (FSCC), two fuel

4. Trend logging

oil (FO) transfer local panels, and the JP-5 local

5. Demand and data logging

control panel. These consoles and panels are an

integrated information and control system. They

The line printer control panel consists of two

provide operator control and monitoring from

indicator lights and three toggle switches. The first

local and remote locations. In most cases, infor-

indicator light, labeled POWER, illuminates green

mation generated by one unit of its system is

to indicate electrical power is applied to the

shared by one or more of the other units.

printer. The first switch is a two-position, spring-

loaded toggle switch labeled FORM FEED. It

FUEL SYSTEM CONTROL CONSOLE

advances the paper in the printer to the next page.

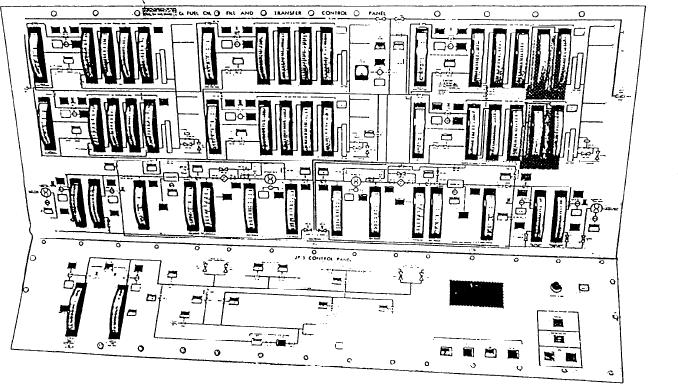

An FSCC is shown in figure 9-6. This console

The second indicator light, labeled ON-LINE,

provides centralized monitoring and control of

illuminates green to indicate the printer is ready

Figure 9-6.--Fuel system control console.

9-9