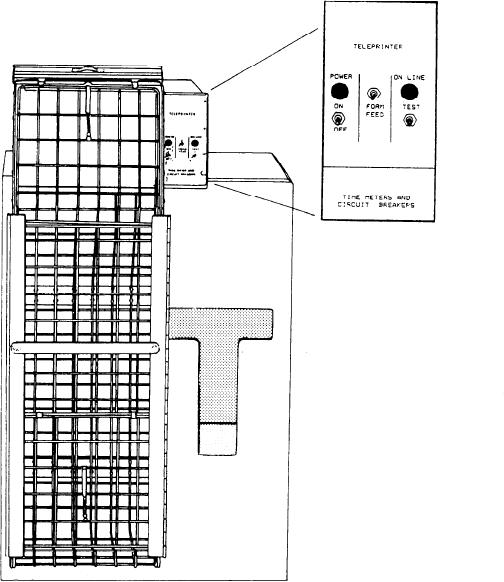

Figure 9-5.--Line printer.

DATA LOGGING.--The data logging func-

commanded to print. Figure 9-5 shows a detailed

tion provides a record of the values and/or status

view of one of the line printers.

of all parameters of interest, either automatically,

at selected time intervals, or upon operator

Bell Logger

demand.

The bell logger prints only bell signals and

ALARM LOGGING.--The alarm logging

replies to those signals. Bell signals include

function provides a permanent record of all

rpm commands, pitch commands, and station in

changes in alarm conditions as they occur, in-

control status. All other logging functions are

cluding both the alarm itself and its acknowledge-

done by the data logger.

ment or reset.

Data Logger

STATUS CHANGE LOGGING.--The status

change logging function records nonalarming

The data logger is responsible for all logging

changes in the discrete status of certain param-

functions not performed by the bell logger. These

eters, such as pump on/off or pump fast/slow.

functions include data logging, alarm logging,

TREND LOGGING.--The trend logging

status change logging, trend logging, and demand

function provides continuous and automatic

print logging.

9-8