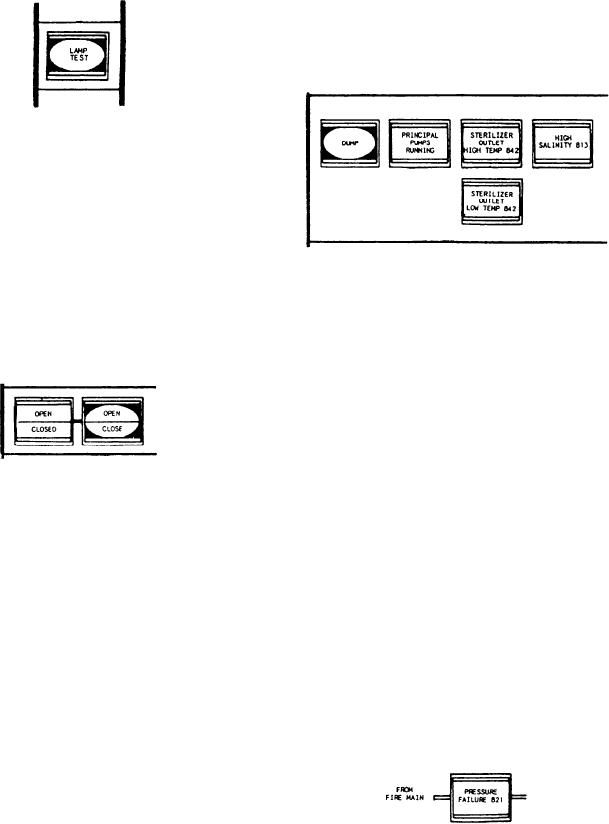

side of the panel. This push button is used to test

indicator, labeled HIGH SALINITY, illuminates

the lamps on the lower panel.

red to indicate the salinity of the distillate has

reached 0.065 equivalent parts per million (epm).

The fourth indicator, labeled STERILIZER

OUTLET LOW TEMP, illuminates red to indicate

the sterilizer outlet temperature has dropped to

160F.

Fill Valves Section

This section consists of four sets of indicator

and control push buttons for the fill valves of the

potable water tanks. Since each set is identical,

only one set of push buttons will be discussed.

The first split-legend indicator is labeled

OPEN and CLOSED. The top portion of the

indicator illuminates green to indicate the potable

The function of each distilling plant is to

water tank fill valve is open. The lower portion

supply fresh water for the ship's potable water

illuminates red to indicate the potable water tank

system. It also supplies untreated distilled water

fill valve is closed. The second split-legend push-

to the GT water wash system, the electronic

button switch allows control of the potable water

cooling water system, and the static frequency

tank motor-operated fill valve.

changers. There are two independent distilling

plants, each producing 4000 gallons of distilled

water per day. Both plants are located in AMR

No. 3.

Saltwater Service System Section

The status of the saltwater service system is

provided by meters and an alarm for firemain

Distilling Plants Section

pressure. Also, there are alarms for the seawater

cooling system pressure in the three AMRs, the

Alarms, lighted indicators, and a push button

engine room, and the air-conditioning machinery

are provided for monitoring and controlling the

operation of the distilling plants. The alarms alert

room. Push-button switches and lighted indicators

provide control and status of cooling water over-

the operator to a high or low temperature of the

board discharge valves in the engine room, AMR

distillate leaving the sterilizer and to a high

No. 2, and the air-conditioning machinery room.

distillate salinity condition. A lighted indicator

The first alarm indicator in this section is

provides the status of the three pumps associated

labeled PRESSURE FAILURE. It illuminates red

with each distilling plant. A push button allows

to indicate the cooling water pressure from the

remote operation of the plant's 3-way solenoid

firemain system has dropped to 110 psig. The

trip valve. Each distilling plant section on the

saltwater section of the ACC contains five

ACC contains four indicators and one control

PRESSURE FAILURE alarm indicators, all of

push button. The indicators and control for only

which function identically.

one plant will be discussed.

The first control push button is labeled

DUMP. It allows the operator to operate remotely

the distilling plant's dump valve. The first

indicator is labeled PRINCIPAL PUMPS RUN-

NING. This indicator illuminates green to indicate

the three pumps associated with the distilling

The first split-legend indicator in this section

plant are running. The second indicator is

is labeled OPEN and CLOSED. The top portion

labeled STERILIZER OUTLET HIGH TEMP.

of the indicator illuminates green to indicate the

It illuminates red to indicate the sterilizer outlet

overboard discharge valve is open. The bottom

temperature has reached 198F. The third

9-40