sampling method will be 1,870 (40,00 - 2,600 =

37,400 x 5%= 1,870). The accuracy rate is computed

mathematically by subtracting the number of errors

from the total number of items inventoried, then divide

the difference by the total number of items inventoried.

For example, the total number of items inventoried is

375 and the number of errors is 24 (375 – 24 = 351, then

351 + 375 = .9360). The accuracy rate is 93 percent.

When inventory accuracy falls below 90 percent, a

bulkhead-to-bulkhead or wall-to-wall inventory maybe

required for the storeroom or storage area involved.

All quantity and location differences found during

the random sampling inventory must be adjusted and

posted in the stock records. However, the differences

that should be counted as errors are as follows:

. Each location difference

. Each quantity difference when the quantity

adjustment exceeds 10 percent of the stock record

balance or the adjusted value exceeds .

When computing the accuracy rate, count the

location and quantity errors in the same stock record as

only one error. Changes to the cognizance symbol,

stock number, unit of issue, unit price, management

codes, and so forth that are required as a result of the

inventory are not considered as errors when computing

the inventory accuracy rate.

SCHEDULED INVENTORY

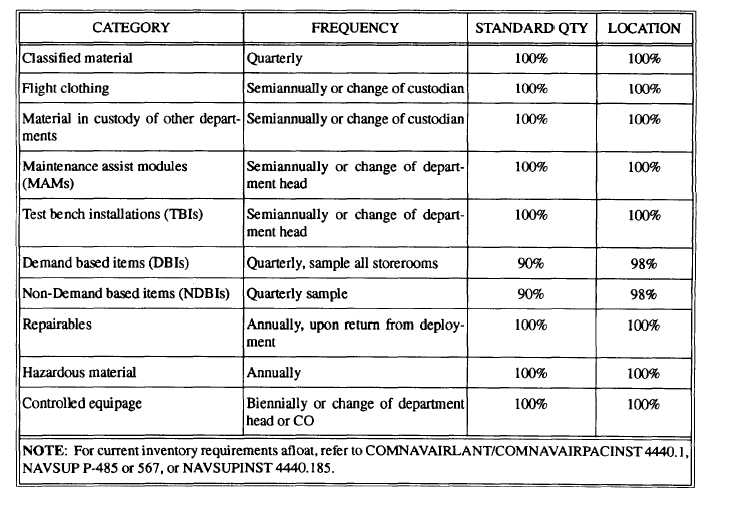

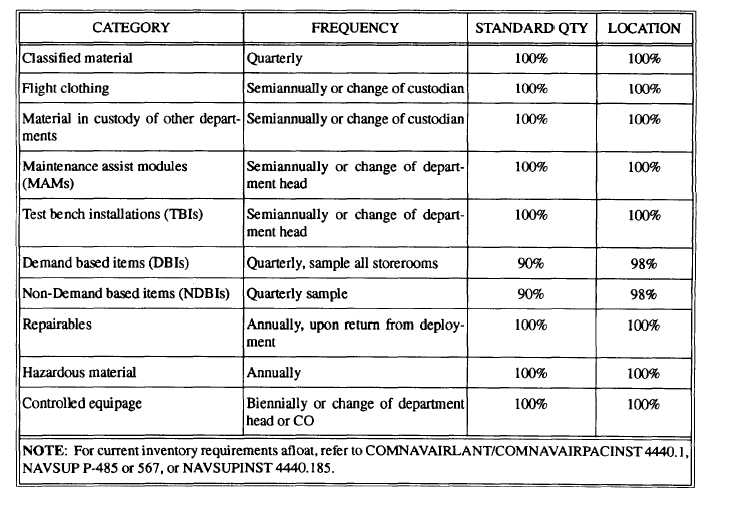

Some items should be inventoried at a specified

interval to ensure effective control of material needed

to support the mission. The inventory requirements in

Table 5-1 are considered the minimum necessary for

effective control of material.

NONSCHEDULED INVENTORY

This is the type of inventory that is conducted to

investigate the inaccuracies in the stock records found

during issue process, random sampling, or supply

inspection.

Nonscheduled inventories also include

those that are occasionally required of certain items as

Table 5-1.-Scheduled Inventory Requirements

5-6