required by the item manager, type commander, or

other authorities. An example of a nonscheduled

i n v e n t o r y is

the

spot

inventory.

A

bulkhead-to-bulkhead inventory of specified

storeroom(s) or a specific commodity that is required

as a result of an unsatisfactory random sampling or

supply management inspection is an example of

nonscheduled inventories.

ASHORE

The NAVSUPINST 4440.115 describes the

physical inventory program for shore activities. The

AKs assigned to shore billets are responsible for

managing only a small portion of supply stock. The

AKs are responsible for the supply assets located in the

aviation support division (ASD)/supply support center

(SSC). Personnel assigned to shore billets should

familiarize themselves with the inventory program to

cope with reorganizations.

Physical Inventory Requirements

The physical inventory required ashore is classified

as the unscheduled and scheduled inventory as

described in the following paragraphs.

UNSCHEDULED INVENTORY.— This in-

ventory is conducted as a result of the following:

1. Spot Inventories of Warehouse Refusals. These

are usually caused by errors between the stock records

and the actual location. A warehouse refusal occurs

when stock point records indicate an on-hand balance

but the material cannot be located to satisfy a

requisition. Processing the warehouse refusal results in

customer credit, referral of the requisition, adjustment

of stock record balance to zero, and the processing of

an inventory adjustment. The procedures for

processing warehouse refusals are listed in enclosure 2

of NAVSUPINST 4440.115. The stock points that do

not elect to use this procedure must conduct a spot

inventory of all warehouse refusals with a total dollar

value greater than 0 (excluding DLA-owned

material).

NOTE: A spot inventory must be conducted for all

sensitive or pilferable items that have experienced a

warehouse refusal.

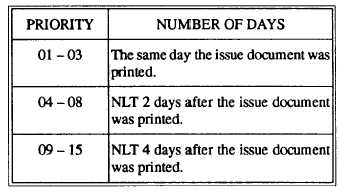

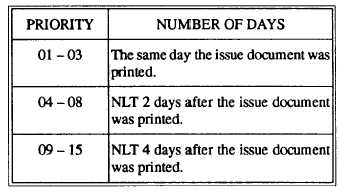

To ensure timely processing of requisitions, the

potential warehouse refusal must be researched and

resolved according to the time frames in Table 5-2.

Table 5-2.-Warehouse Refusal Time Frame

2. In-house Receipt Losses. An inventory must be

conducted for all in-house receipt losses with a dollar

value over 0.

3. Location Survey.

An inventory must be

conducted if the following stock record differences are

identified:

l

l

l

The material was found in an unrecorded

location

Potential gains (material is in the location, but

stock record shows zero balance)

Potential losses (material not in location, but

stock record shows there is material on-hand)

4. Selected Item Inventory. This is requested

locally when a known or suspected imbalance exists

between the recorded and actual on-hand balance, or to

resolve a Report of Discrepancy (ROD).

5. Naval Inventory Control Point/Defense Supply

Center (NAVICP/DSC) Directed Inventory. The

physical inventory requests are generated by the

NAVICP/DSC when a bounceback is received and the

research

exists:

l

l

reveals that one of the following conditions

The bounceback is for condition code A

material and the on-hand system asset in A

condition is less than the projected quarterly

demand.

The bounceback is for a fleet-controlled item

(any condition).

NOTE: The NAVICP/DSC freezes their records to

prevent processing of requisitions until the results of

inventory is received.

The NAVICP/DSC may also request for location

reconciliation to resolve record/quantity mismatches.

A physical inventory of assets is also required before

5-7