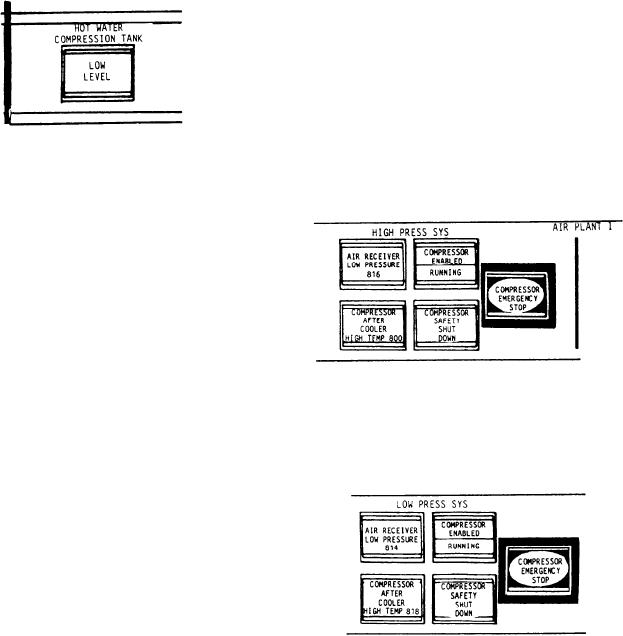

the indicator illuminates white to indicate power

water compression tank has dropped below the

is being supplied to the compressor. The bottom

preset limit.

portion of the indicator illuminates green to

indicate the compressor is running. The third

indicator, labeled COMPRESSOR AFTER

COOLER HIGH TEMP, illuminates red to

indicate the HP aftercooler temperature is above

the preset limit. The fourth indicator, labeled

COMPRESSOR SAFETY SHUTDOWN, illumi-

nates red to indicate an automatic compressor

shutdown has occurred. The push-button switch,

labeled COMPRESSOR EMERGENCY STOP,

allows the operator to stop the HP air compressor

The waste heat exchanger transfers heat

in the event of an emergency.

generated by the SSDG to the waste heat

water circulating system. The waste heat water

circulating system supplies heat to the fuel transfer

heaters, the fuel service heaters, the LO purifier

heater, the distilling plants, and the hot potable

water accumulator tank heating coil. The system

has four waste heat exchangers and four

circulating pumps. The pumps start and stop

automatically with the starting and stopping of

their associated SSDG. The circulating equipment

is located in the three AMRs and the engine room.

The system is designed for automatic start-up and

The LP air section of the ACC consists of five

unattended operation.

control indicator push buttons. The indicators and

Compressed Air Plants Section

controls in this section are functionally identical

to those discussed in the HP air section, except

The status of the HP air system and the LP

they are for the LP air compressor.

air system is provided by alarms and visual

indicators. Push buttons are provided to stop any

of the four compressors in an emergency. The

alarms alert the operator that the air receiver

pressure is low, when the HP system after-cooler

temperature is high, when the LP system dryer

discharge temperature is high, and when an

automatic compressor safety shutdown has

occurred. A split-type indicator shows when

power is being supplied to the compressor and

when the compressor is running.

There are two air plants. Each one has an HP

Main Engines Starting

air system and an LP air system. One of the air

Air System Section

plants is located in AMR No. 2 and the second

is located in AMR No. 3. Each of the four

The starting air compressors in the main

compressed air systems is provided with indicators

engine starting air system are designed for either

and a switch at the ACC. The systems are

local or remote start-up. This section provides

designed for local start-up and unattended

controls to allow the operator at the ACC to

operation. Since the two air plants are identical,

engage or disengage the compressor clutch. For

only one plant will be discussed.

the controls to be operational, the local clutch

The HP air section of the ACC consists of five

controller selector switch must be in the REMOTE

control indicator push buttons. The first indicator

position. This section also provides indication of

is labeled AIR RECEIVER LOW PRESSURE.

the clutch status and alarms for low compressor

It illuminates red to indicate the HP air receiver

LO pressure and failure of the clutch to engage.

pressure is below the preset limit. The second

A meter provides a continuous reading of the air

split-legend indicator is labeled COMPRESSOR

discharge pressure.

ENABLED and RUNNING. The top portion of

9-34